A roof over your head does keep you safe from Melbourne weather conditions (which are often unpredictable!), but have you ever thought about the purpose of your roof in detail? The roof flashing is an important part of any roofing system, as it’s essentially a protective barrier against water.

Whether you’ve worked on your roof before or are due to upgrade the worn materials, it is a good idea to be aware of the different flashing profiles and what will be best for your roof.

Let’s outline the common flashing profiles used in Australian roofing, discuss how they function for different roofing, and help you make a decision.

Why is Roof Flashing So Important?

Roof flashing isn’t just important, it is legally mandatory for most buildings to have it installed. As per the National Construction Code (NCC) performance requirements (FP1.4 in Volume 1 and P2.2.2 in Volume 2), there are specific requirements for flashing materials installation, and fixings to create that watertight seal. This includes:

- Roof flashings and cappings must be purpose made, machine-folded sheet metal sections of material compatible with all up and downstream metal roof covering materials in accordance with 2.2(2).

- The type of fasteners for flashing and cappings must comply with 2.5.

- The fixing and fastener frequency for flashings and cappings must comply with Table 2.7.

- Joints in flashings and cappings must be no less than 75 mm, lapped in the direction of the fall of the roof and fastened at intervals no more than 40 mm.

- Wall and step flashings must be fastened into masonry walls with galvanised or zinc.

- Lead flashings must not be used with prepainted steel or zinc/aluminium steel or on any roof if the roof is part of a drinking water catchment area.

- Anti-capillary breaks must be installed in accordance with Figure 7.2.7a and be for flat surfaces (10 mm/30 degree fold) and all other surfaces (10 mm/90 degree or 135 degree fold).

- Acceptable flashing configurations are shown in Figure 7.2.7b and Figure 7.2.7c.

Flashings of penetrations must comply with this criteria:

- Collar flashings must permit the total drainage of the area above the penetration.

- On completion of installation, the roof structure needs to be restored to its original strength by installing roof trimmers and soaker supports as necessary.

- The type of fasteners for flashing and cappings must comply with 2.5.

- Lead flashings cannot be used with prepainted steel or zinc/aluminium steel or on any roof if the roof is part of a drinking water catchment area.

- Some of the acceptable flashings for penetrations are shown in Figure 7.2.7d, Figure 7.2.7e, and Figure 7.2.7f.

- Clearance for heating appliance roof support members must be in accordance with Part 12.4.

As mandated in Part 7.2, wall and step flashing need to be fastened into masonry walls with galvanised or zinc/aluminium sheet metal wedges at each end of each length and at intermediate intervals of not more than 500 mm and must overlap. For these reasons, it is better to call a professional, qualified roofer to do the job.

Why Should You Install Flashings?

With flashings, you won’t need to worry about ozone and UV exposure. Flashing is a roof material that reflects more of the UV rays more than traditional roofing components, such as bricks or shingles. Why should you install them?

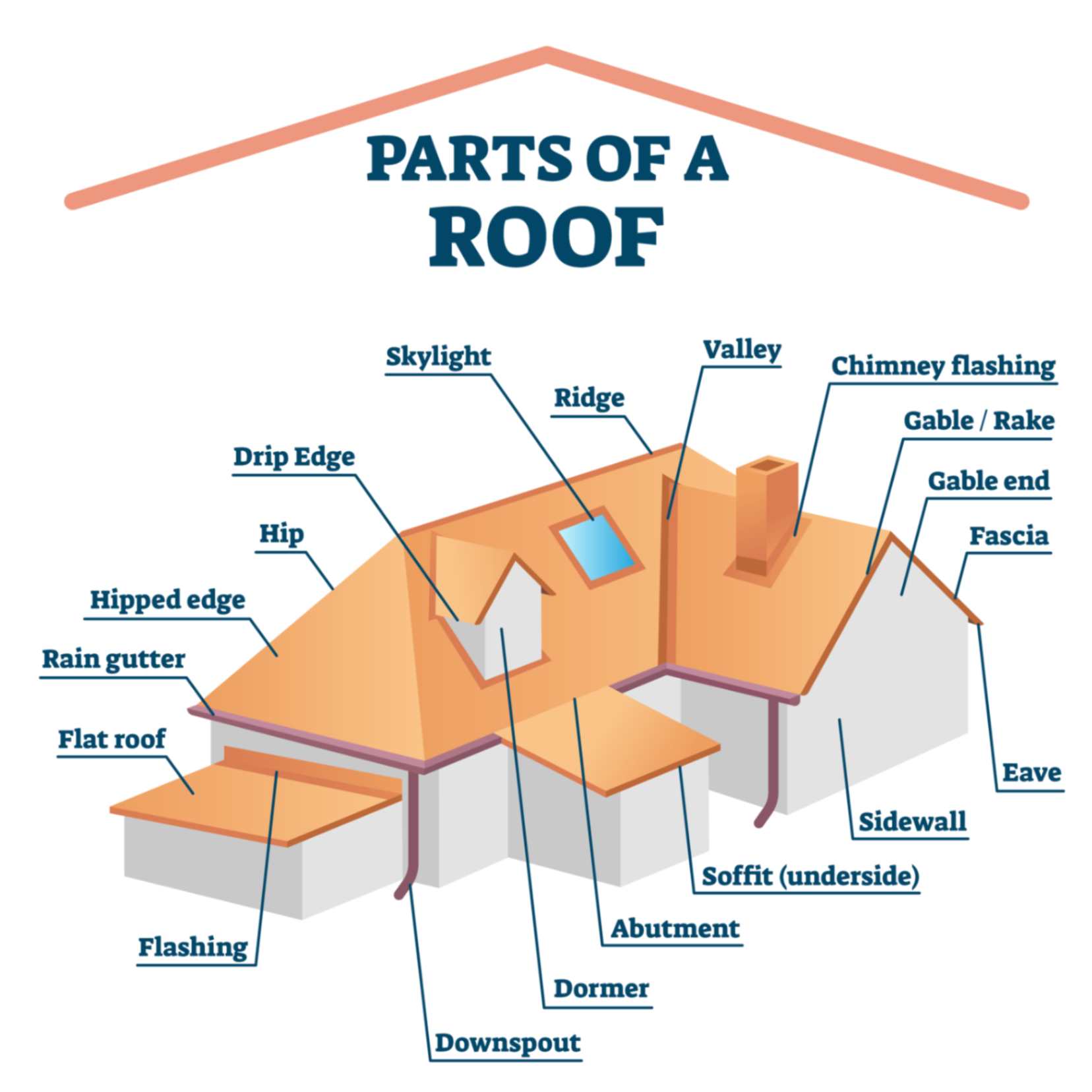

- Flashings protect areas of your roof prone to water accumulation, such as windows, skylights, walls, roof valleys, vent pipes, or chimneys. Barge capping creates a junction between barge boards and the roof sheeting for a waterproof finish.

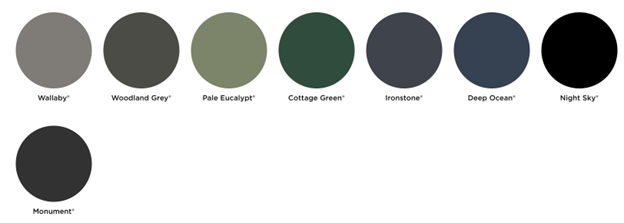

- There are many colours and styles. If you choose Colorbond flashings, pick pale tones such as Dover White or Surfmist, Mid Tones such as Bluegum or Gully, or Deep Tones such as Deep Ocean or Monument.

- Flashings last up to 70 years. With Zincalume and Colorbond steel, BlueScope has a warranty against weathering and corrosion for up to 30 years for Zincalume and 36 years for Colorbond.

- Flashing is eco-friendly as it is lead-free and does not contaminate soil or water sources.

- There are superior Colorbond and Zincalume options instead of old-school copper and aluminium!

For example, you might use step flashing around the base of your chimney, valley flashing (where your two roof slopes meet), window flashing surrounding the roofing framework, or drip edges that channel water into your roof guttering.

If you’re hoping to install a brand new roof, should you replace or reuse your current flashing? Generally, it is recommended to replace the flashing entirely. Flashing deteriorates over time (it’s general wear and tear from the elements), may not be compatible with new materials, isn’t likely to have gaps or defects, and all in all won’t null your warranty. For new roof installations, new materials need to be used in order to qualify for warranty, such as BlueScope steel.

The purpose of the roof flashings (wherever they are installed) is always to direct water away from potentially vulnerable areas of the roof where it’s likely to enter and cause damage! If you would like more insight, read through the top benefits of custom flashing for roof longevity.

Affordable Flashing at Roofing Options

Cut to custom lengths, available in 28 colours, and manufactured using 100% Australian-made steel, what types of flashings can you order at Roofing Options?

Ridge Flashing

Add finishing touches to your roofs! Ridge Flashing is used at the apex of 2 roof lines to provide a continuous seal and finish along the ridge. The size of the edge break on your flashing should conform to the rib height of the sheet profile to which the sheet is attached.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Window Flashing

These are custom-made cap, seal and finish building frameworks and external brickwork surrounding windows and potentially external door frames.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Valley Flashing

A Valley Gutter sits between two internal roof slopes angled to suit each pitch, with a return hook fold to minimise the chances of water transferring into your roof space.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Box Gutter Flashing

A custom-made square or rectangular gutter that is used within the boundaries of the roof, box gutters need structural support underneath to improve strength and stiffness and to minimise damage caused by roof traffic.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Barge Flashing

Installed at the junction between a fascia or barge board and roof sheeting, barge flashing conforms with the rib height of the roof sheet profile to which the flashing is attached.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Apron Flashing

Installed to prevent water from penetrating the juncture where a vertical surface intersects a roof, apron flashing is recommended when the base of the flashing faces strong winds.

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Parapet Flashing

- Manufactured using COLORBOND® & ZINCALUME® 0.55 bmt

- Custom Lengths up to 8m long

- Total Girth/Widths to 1.2m

- Sold per L/M

Roofing Options have standard flashing profiles or custom-made fabricated from 1200mm wide Colorbond, Zincalume and Galvanised steel that fits with your existing roof structure. Custom-made flashings include barge capping, apron flashing, valance gutters, and soaker flashings.

Colorbond Steel and Zincalume in Detail

Colorbond Steel roofing makes perfect sense for properties of all types. Why? Colorbond has been carefully tested in Aussie conditions, so it is guaranteed to deliver outstanding performance for flashings. Let’s look at Colorbond in detail and why you should invest in it for your residential, commercial, or industrial property.

- It has five layers of protection. Coated in industry-leading Activate technology, it is further improved with a pre-treatment, primer and a baked-on topcoat. In short, it’s the best you can get for roofing.

- It is thermally comfortable with Thermatech solar reflectance technology since it pushes back the sun’s heat on hot days. Thermatech is available in every core colour except Night Sky.

- Every Colorbond product is made from recycled materials, so the steel can always be reused. Nothing goes to waste, so it can be used for longer.

- Colorbond is assessed in outdoor sites across Australia, including corrosion testing, durability testing, application testing, and outdoor exposure testing. This way, it’s used for numerous manufacturing applications and common building products.

- Flashings made from Colorbond are bushfire compliant (AS 3959:2018) and do well when exposed to extreme levels of radiant heat and exposure to flames at the fire front.

- You receive the support of BlueScope, one of Australia’s largest manufacturers. It is backed by one of the most robust product warranties for eligible applicants.

- Maintain Colorbond easily with clean, fresh water.

Dealing with a leak where your roof meets a wall with no external or new flashing? If there’s plans in place to install flashing across your entire roof or a portion that has been damaged, the Roofing Options Centre team are experts you can rely on.

Order Colorbond Steel Flashing at Roofing Options!

Whether you’re a homeowner, builder, contractor, or a passionate DIY’er, we deliver roofing supplies to Frankston, Carrum Downs, Cranbourne, Berwick, Dandenong, Officer, Clyde, Langwarrin, or anywhere in Melbourne.

Purchase Laserlite 2000 & 3000, Palram Sunsky, Sunlite Twinwall, Sunglaze, Ampelite Solasafe, custom made flashings, downpipes & accessories, gutters & metal fascia, rainheads & sumps, or steel roof sheets through us.

Browse our online store, contact us through our website or visit us personally in Cranbourne, Coburg, or Campbellfield. We have a number of payment options to get your roofing project started.