Polycarbonate roofing materials expand and contract with temperature fluctuations (hot to cold, cold to hot) and this thermal movement process must be considered before and during any installation work.

Whether you’re a passionate DIY’er or are looking around for a roofing installer, it’s good to be aware of expansion-friendly installation practices.

If you’ve never heard of polycarbonate or want to know more about its amazing thermal properties, read on!

What is Polycarbonate Roofing?

Polycarbonate is a very strong thermoplastic material that is also lightweight and capable of handling extreme temperatures. This resilience makes it an effective roofing material for many roofing applications.

It is virtually unbreakable, with 250 times the impact strength of float glass and 30 times that of acrylic. There are different variations of polycarbonate on the market, such as:

- The Laserlite brand and product range have been synonymous in the world of Polycarbonate Roofing for many years. Laserlite offers a range of Polycarbonate roofing with various profiles and colours, including Laserlite 2000 and Laserlite 3000.

- Palram SunskyI.Y. Polycarbonate Sheet Roofing was one of the first introduced to the Australian marketplace. Offering a host of designer colours and standard profiles, Sunsky has a product to match your performance and project needs with Sunsky 2001 and Sunsky 3001.

- All Ampelite Solasafe Polycarbonate roof sheeting provides 99.9% protection from harmful UV rays and offers various light transmission values throughout its range. With three-tiered performance levels to choose from, Solasafe has a product to suit your needs and colour to suit your home and project.

- Palram’s EZ Glaze offers an innovative design, elegant glass-like appearance, versatility, low maintenance and sustainable performance. EZ Glaze incorporates a proprietary profiled design, enabling it to be installed over rafters. It’s easy to install as the panels are screw-fixed to the supportive structure and joined by overlapping, providing you with a window to the sky.

Use polycarbonate for garages, decks, patios, sheds, conservatories, and even pool covers or roofing for industrial warehouses. If you have a specific outdoor plan in mind, polycarbonate panels will do the job nicely.

Why is thermal expansion so important to understand?

In terms of thermal expansion, the material shrinks in cold temperatures and expands in high temperatures (but it needs structural support to stop deformation or sagging). Over time, this cycle causes polycarbonate to lose flexibility, and the components won’t expand or contract. The coefficient of thermal expansion for polycarbonate is around 0-65 mm/°C, so a 10-metre panel can expand or contract by almost 7 mm with a 10 °C temperature change.

Thermal expansion also affects insulation. Multiwall panels have insulation air chambers that reduce heat transfer, but these thermal breaks keep heat out in summer and retain warmth during colder months.

The U-value (or thermal transmittance) depends on the panel thickness and chamber design; it typically ranges from 3.8 W/m²K for single-layer panels to 0.9 W/m²K for multi-chamber designs.

If you’re noticing loose seams or signs of deterioration, thermal expansion results in cracks on the sheets, especially near the two screws. The rigid fixing of screws on the sheet leaves no room for the polycarb to move.

Let’s take a look at some installation practices that are expansion-friendly.

Although polycarbonate is durable, if you’d like to build a pergola, care must be taken during installation for long-term performance.

Always plan a space for the polycarbonate to move

You want to keep enough room to compensate for thermal expansion by leaving a small gap where they meet another object (such as a pergola wall).

Since sheets expand often along their length, pay attention to this direction. Multiwall polycarbonate sheeting moves along the ribs’ direction, and profile sheets expand along the corrugation lines.

Pre-drill oversized holes

These holes could be around the fixing’s location. Expanding these holes will put a stop to stress and ensure the materials last when exposed to hail, wind, rain or sunshine.

Never over-tighten

Secure your fixing for safety and durability. Over-tightening can cause distortion and excess stress, which can ultimately cause material failure.

Use suitable fixings

For example, flexible EPDM gaskets allow just enough free movement for the sheets to contract and expand. This creates a seal against leaks and reduces stress and microcrack formation around the fixing.

You can combine these gaskets with self-tapping screws for timber purlins or self-drilling screws for metal purlins. Roofing Options offers corrosion-resistant purlins for long-term service.

Use polycarbonate-compatible sealants

Sealants can include silicone, but some options aren’t ideal for polycarbonate.

If it’s unavoidable, use a neutral cure or non-acidic silicone approved for polycarb. Do not use bitumen foam infills as they will cause some damage.

SUNGLAZE is a reliable polycarbonate roof system with free expansion joints, and you don’t need to worry about pre-drilling as they click in place! Sheets expand and contract while secured to your roof system. Flat and solid panels with edges that fit into a standing seam glazing system, use SUNGLAZE for home, outdoor roofing or more complex engineering.

Repair and inspect your roof on a regular basis and look for signs such as hairline fractures in the material.

When you order polycarbonate, Roofing Options will give you recommendations on installation and how to take care of the material.

How do you decide on the panel thickness?

Figure out the thickness of the sheet by considering the wind load and deflection/bend radius required. Usually, a solid flat sheet’s thickness ranges from 1.6mm to 15mm:

- Corrugated profiles are from 0.6mm to 2.0mm

- Ultra-think solid flat sheets from 0.4 to 1.2mm

- Multi-wall thickness ranging from 4mm to 25mm

On average, the range for outdoor skylights is between 3mm and 10mm. Thinner than 3mm renders polycarbonate sheets impractical, and the sheets will be prone to damage. Thicker than 10mm works for some projects, but the overall cost is high.

What are some climate considerations?

It is recommended by roofing professionals to use 3mm of polycarbonate sheets in areas with extreme climates as they handle hail, snow and ice better than thin-walled alternatives. For example:

- 6 to 10mm multiwall SUNLITE is a good covering for DIY greenhouses, gazebos, cold frames and DIY garden sheds.

- 10 to 16mm multiwall SUNLITE DIY are great for sunrooms, conservatories, pool enclosures, permanent patio canopies, and carports.

- 8mm corrugated SUNTUF is a good lightweight garden roof cover or patio rain cover.

- SUNTUF Beehive and EZ Glaze can be used for a glass roof replacement, a solid roof pergola and a hail-resistant canopy.

- Panel systems such as skylights, designed canopies, and clear polycarbonate roofing.

What Are The Benefits of Polycarbonate Sheets?

According to Polycarbonate Roofing Australia, each polycarbonate sheet is manufactured with protective coatings to block harmful ultraviolet rays, prolonging longevity and reducing potential discolouration. Here are some of the advantages!

- It stands up to harsh weather, so it’s perfect if you live on the coast or are putting together a project that needs strong impact protection. Polycarb adds long-term value to any structure.

- Supports residential, commercial, and industrial customers and is flexible for everything from home remodelling to agricultural storage.

- Multiwall and twinwall polycarbonate sheets maintain comfortable environments by moderating temperature fluctuations. The nature of polycarbonate is adaptable!

- There are many tints, finishes and profiles for property owners to select, such as for a pergola roof, a skylight, or to complement an existing structure. Buildings can achieve a cohesive, modern look.

What about industrial fibreglass? Roofing Options is one of the best roof sheeting suppliers in Melbourne for all kinds of polycarbonate, sourcing products from trusted manufacturers. We have over 60 made-to-order profiles available to order.

Laserlite 3000

Laserlite 3000 polycarbonate is one of the most durable and technologically advanced polycarbonate roofing products.

- Profiles Available: Corrugated & Greca

- Effective Cover (per sheet): 760mm

- Roof Pitch Required: Min 5 degrees

Suntuf EZ Glaze

Suntuf EZ Glaze creates a glass-like appearance after eliminating the need for purlins running throughout the width of your roof space. EZ-Glaze is smart, elegant and glass-like.

- Profiles Available: 2 Rib Sheet

- Effective Cover (per sheet): 600mm

- Roof Pitch Required: Min 5 degrees

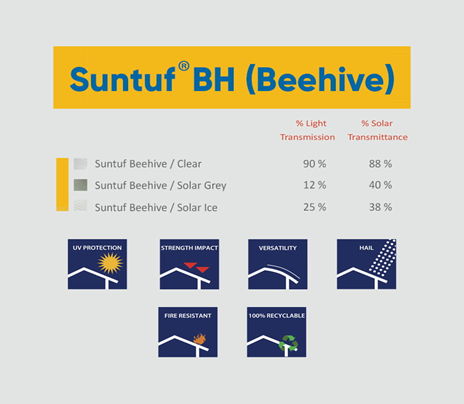

Suntuf BH (Beehive) Polycarbonate

Being three times thicker than standard polycarbonate roofing, Suntuf Beehive Polycarbonate offers strength and durability while boasting the highest impact resistance available in profiled polycarbonate today.

Suntuf BH produces 100% diffused light, resulting in greater flexibility and suitability for both residential and commercial use. The underside of the Suntuf BH polycarbonate sheet has an embossed surface that adds a new and fresh appearance to your project.

If you’re in need of roofing supplies in Frankston, Cranbourne, Dandenong, Narre Warren, Langwarrin, Officer, Clyde, Endeavour Hills, or anywhere across Melbourne, Roofing Options is a roofing expert you can trust with your property’s roof sheets.

Want to Install Polycarbonate Roofing in Melbourne? Contact Us!

With everything builders, homeowners, contractors or DIY enthusiasts need to transform exteriors, Roofing Options is a leading source for roofing supplies in Melbourne.

Supplying Colorbond roofing supplies, sheets, panels, custom flashing, downpipes, and a full range of DIY kits, you’ll be fully prepared to get to work. We provide hassle-free online shopping with home delivery included. Once an order is made, your products will be shipped in a safe and secure manner. Wherever you’re located, we have the perfect roofing supplies to match!

- Our team of experts will answer all your queries promptly

- Specialist advice or even a quote, we’ve got you covered

- Three locations across Melbourne for local pick up

- Upload photos, plans and hand-drawn details

- Upload your order or flashing details to expedite the order process

Contact us today to learn more about our product catalogue and what polycarbonate will be best for you.