Roofing is constantly exposed to the weather, and sometimes water can infiltrate the structure of the building, which you do not want to happen! Roof flashing is a thin material (generally metal) installed at multiple points on a roof to direct water away from critical areas, such as your home’s foundation.

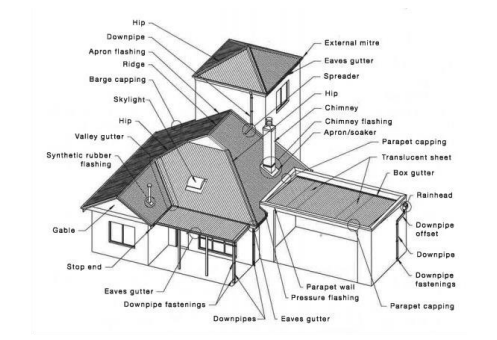

According to the Victorian Building Authority, a roof flashing is defined as a rigid or flexible material fixed over, against, or built into an abutment to form a watertight joint, and this includes apron flashings, soaker flashings, transverse flashings, pressure flashings, barge capping, and parapet capping.

This article will be your ultimate guide to flashings, the types you can choose from for your home, common materials, and why they are necessary for Australian properties.

Why is Flashing Important?

Why is flashing so important? Flashing sits over the top of the building wrap (except at the head where it sits under the wrap) to redirect rainwater and prevent it from leaking into the interior of the walls, such as damaged frames or floorboards.

- Flashing acts as a barrier to guide water to the gutters, stopping it from seeping into the most vulnerable parts of a roof: the joints or seams.

- Flashing can be installed around skylights, chimneys, vents, or valleys where the roof changes direction or material, and without proper flashing, you could be up for a lot of expensive damages.

- Moisture can ruin insulation, leaks can cause stains, peeling paint, drywall damage, and electrical problems if it were to reach your wiring.

- Or worse, exposure to moisture causes wood to rot (icky mould and mildew), which has the potential to cause health issues.

Without flashing, you can be penalised by the Victorian Building Authority. As of February 1st 2019, the National Construction Code states that flashing is a mandated requirement in every residential window with masonry veneer or lightweight construction cladding in Australia, so ensure that you have one.

Flashing Installation: Do You Need To DIY?

A good flashing is non-negotiable, and there are also foolproof ways to install them. You can do it yourself, but it is recommended to hire a roofing contractor who knows exactly what they’re doing down to the nuts and bolts.

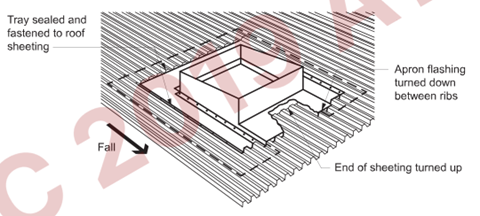

For example, according to the National Construction Code, certain metals cannot be used in association with another metal, or apron flashing must be turned down between ribs, the end of the sheeting turned up, as well as a multitude of other requirements! In terms of water discharge, where an eaves gutter is provided, sheets must overhang the fascia, or end batten where there is no fascia, by no less than 35mm. The average homeowner (unless you’re super handy with measurements and tooling) will not install roof flashing to Australian standards.

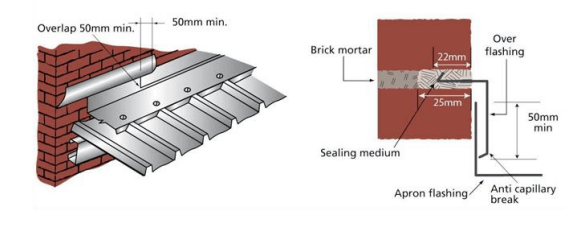

Here is another complex example of the requirements for a traditional raked joint and step method.

The over-flashing must cover the upstand of the flashing by a minimum of 50mm, must be chased into the wall by at least 25mm and must incorporate an anti-capillary break, and must have a minimum depth of 22mm of the chase.

For a sloping wall cut method, the upstand of the flashing needs to be 100mm, the wall and stop flashing must incorporate a 10mm anti-capillary break, and be fastened to the roof at no less than 500mm centres. A roofing contractor who is licensed (and with experience) and in compliance with the acceptable construction practice must satisfy the Performance Requirement P2.1.1.

Here are some other installation techniques that you can potentially DIY, but again, it is recommended to reach out to a professional.

- Measure and prepare the area where the flashing will be installed, including the correct dimensions. The surface is prepared by cleaning it of debris so it is dry to allow for sealant adhesion.

- Flashing is typically installed along valleys, ridges, and around chimneys for pitched roofs. Start at the bottom and work your way up, overlapping each piece to direct water away from the roof. Again, this is a complex job and should be done by a roofing contractor.

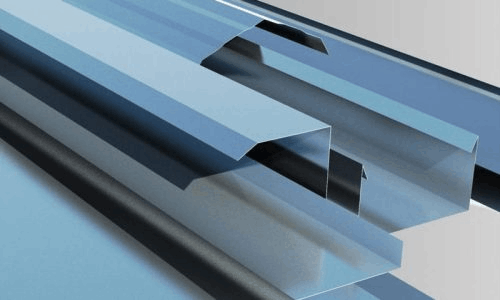

- Corrugated roofs require flashing that accommodates the ridges and valleys of the corrugated sheets. Custom-made flashings can fit these profiles for a snug fit and effective water diversion.

- Flat roofs require careful attention so the water doesn’t pool. Flashing should be installed at all seams and joints, and proper drainage should be ensured to direct water off the roof.

What can be challenging with flashing installations?

Complex roof designs with multiple angles and intersections can make flashing installation challenging. Thankfully, if you’re planning to go the DIY route, custom-made flashings can be designed to fit these profiles for easy water diversion.

When combining different materials (such as metal roofing with timber or brick), flashing materials need to be compatible to prevent corrosion and provide a watertight seal. If you’re unsure of the installation process but would rather do it yourself, consider these trends for your next roofing project!

The joints in flashing must overlap no less than 75mm in the direction of flow, be fastened and secured at intervals of no more than 40mm, and have a sealant between laps. As a DIY’er, you may not have the expertise to implement these specifications.

Types of Roof Flashing

Not every home has the same-shaped roof, so there’s a flashing type for every household. What are some of the types you can consider?

Roof flashing is installed at intersections and joints in the roofing system and pushes water away from these vulnerable areas, putting a stop to leaks and water damage.

Deck flashing is used where the deck meets the house, in particular where the deck’s ledger board attaches to the building. This flashing stops water from entering the joint between the deck and the house, which can lead to rot and structural damage.

Flashing around doors and windows directs water away from these openings, preventing leaks and water damage to the interior of your home. Let’s take a look at types of roof flashing in more detail:

- Apron flashing, which is an over-flashing where a roof abuts a vertical wall or penetration

- Soaker flashing, located on the underside of the roof cover (the upper side of a chimney)

- Transverse flashing runs across a roof, such as ridge capping

- Pressure flashings can only be used on a smooth masonry wall

- Barge capping runs with the roof covering the sides of the roof

- Parapet capping is used to waterproof a parapet wall

If you would like to learn more about roofing (such as guttering systems), have a read of how rain gutter downpipes protect your home from water damage.

What Roofing Materials Are Used in Flashing?

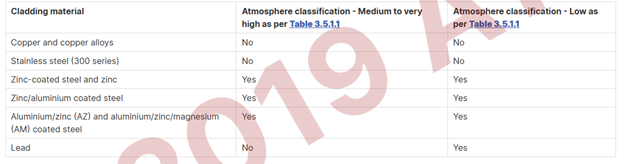

What materials and products are commonly used in the roof and wall cladding industry in Australia? Metal materials such as copper, stainless steel, aluminium, metallic-coated steel, steel coated with an alloy of aluminium and zinc, or galvanised steel coated with a layer of zinc, Zincalume®.

What About Colorbond® Steel?

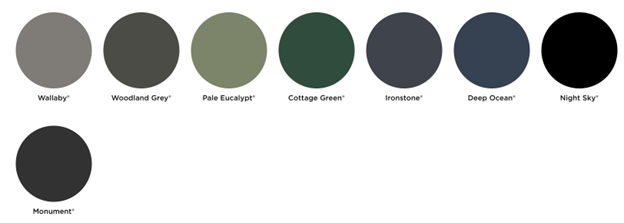

Known for its durability and resistance to corrosion, Colorbond® steel is a popular choice for flashing in Australia. It comes in a variety of colours to match your roofing system. Let’s take a closer look at Colorbond Steel:

- With five layers of protection, Colorbond steel has industry-leading enhanced corrosion resistant Activate technology, further improved with a pre-treatment, primer and a baked-on top coat.

- Colorbonds’ core colour range in the Classic and Matt finish features a specially designed Thermatech solar reflectance technology, so this reflects more of the sun’s heat on hot, sunny days.

- To help create a circular economy, every Colorbond steel product uses recycled materials, and the steel itself is 100% recyclable.

- Roofing, walling, gutters and downpipes are compliant with bushfire-prone areas as defined in AS 3959:2018.

- Colorbond is easy to maintain with clean, fresh water. Prolong its life and retain its attractiveness for longer periods of time.

- Get the support of BlueScope, one of Australia’s largest manufacturers.

- Colorbond is tested in all Australian conditions, from the cold to dust, rain, wind, or hail, and assessed at outdoor sites around Australia and in accelerated laboratory testing.

ZINCALUME®, on the other hand, is suitable for coastal areas if you’re concerned about saltwater exposure. Like Colorbond, it is resistant to corrosion. Why choose Colorbond guttering? With a range of styles, colours (22 core and 6 in a premium Matt finish), Colorbond is perfect for residential, commercial, industrial properties, and even architects or builders with plans. This goes for your flashing choices.

Need a Reliable Roofing Supplier? Call Roofing Options

Protect your home from water infiltration with flashing that gets the job done. Now that you know the importance of flashing, its types, materials, installation techniques, and challenges, your home will always be free of leaks and damages.

For custom-made flashings, steel roof sheets, gutters & metal fascia, Laserlite 2000 & 3000, downpipes & accessories, Suntuf Polycarbonate roofing, Sunlite Twinwall, Velux Fixed Skylights, or something specific for your roof, Roofing Options is your go-to supplier.

Whether you’re on the hunt for roofing supplies in Reservoir, Lalor, Broadmeadows, Langwarrin, Thornbury, Preston, Coburg, or Endeavour Hills, we have everything you need to upgrade your old roofing system.

Contact us today by sending an online enquiry or visiting our Cranbourne, Coburg, or Campbellfield stores! Feel free to check out our online store for a better look at our product catalogue.