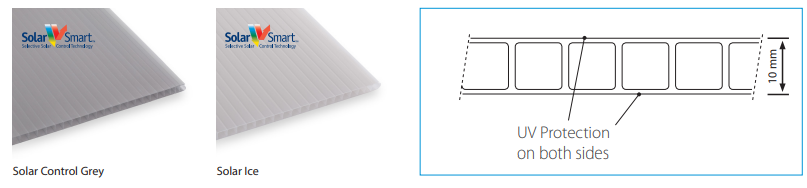

‘Sunlite twinwall sheeting combines the strength of polycarbonate with superior insulation due to its cellular structure, so it’s an enticing roofing option for residential and commercial spaces alike. In fact, it is the only twinwall sheet available that showcases SolarSmart technology, which lets in more visible light and reduces heat-generating infra-red radiation.

Coming as standard with double-sided UV protection, it provides 99.9% protection from harmful UV, and with impact resistance 250 times the strength of glass. This makes it the perfect material for both domestic and commercial structures such as walkways,pergolas, facades, skylights, and more. Great, right? So how do you install it?

This article is a great guide to DIY installation and tips that will help you put together a perfect, comfortable patio this summer.

How Do You Go About Installing Sunlite Twinwall?

There are many benefits to Sunlite twinwall, such as high light transmission, weather resistance, lightweight, a high performance rating, and it is very easy to handle/install.

You might want to install Sunlite for architectural roofing/glazing, sidelights, conservatories, covered walkways, industrial roofing, covered swimming pools, residential roofing, agricultural greenhouses, displays/signage, or something else. Sunlite can be installed in two ways:

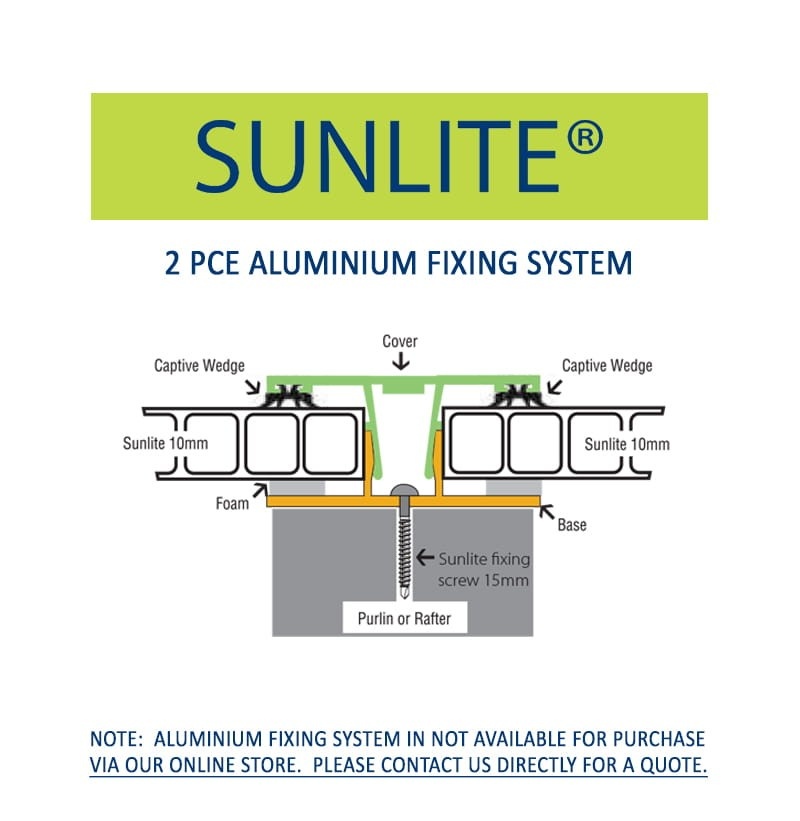

On top of purlins. When your structure has them, fixing screws are placed through the Sunlite joiners and screwed into the purlins to be held in place.

The rafters only. Normally, there aren’t purlins in these designs, but H-bar joiners sit on top of these rafters for a clean appearance. For this to be possible, rafters must be set apart exactly the same distance as the joins in the sheet.

Here are some important things to note before any installation of Sunlite Twinwall takes place.

- Carefully read the installation instructions before you start

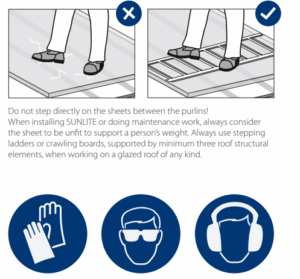

- Always exercise extreme care when working on a roof

- Never walk directly on the sheeting; use walking boards along purlins

- Always wear eye protection when using a cutting tool

- For safety reasons, Palram recommends the use of a safety mesh for installations above 3 metres in height

Do not step directly on the sheets between the purlins! When installing Sunlite, always consider the sheet to be unfit to support a person’s weight.

Use stepping ladders or drawing boards, supported by a minimum of three roof structural elements, when working on a glazed roof of any kind.

What tools do you need?

- Cordless drill/driver

- 5/16 and ¼ hex drivers

- Rubber mallet

- Clamps

- Tape measure

- Set square

- Circular saw

- Hacksaw

- Handsaw

- Drill bits

- Glovers

Here are the steps to installing Sunlite roofing in Melbourne!

- Always use Sunlite sheets with the ribs running vertically with the direction of the fall

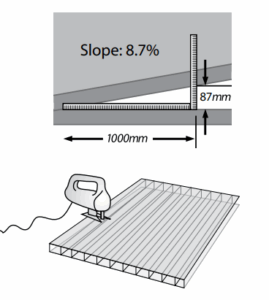

- Make sure there is an adequate fall of a minimum of 5 degrees (87mm per 1000mm). A good fall will aid you in keeping the sheets clean.

- Cut J Joiner alum profiles 50mm shorter than the required length.

- Cut Sunlite sheets to the required length. They can be cut with standard wood or a metal saw with a fine-tooth blade. Saw blades designed especially for plastic yield the best results. If the Sunlite width needs to be reduced, trim as close to the last rub to obtain better clamping action.

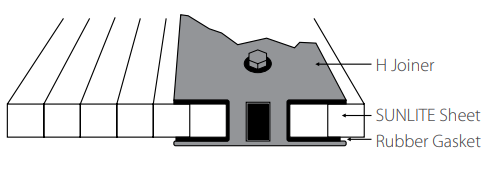

- Place the first H jointer on the structure. The maximum allowed end overhang is 50mm.

- When installing on the rafters or battens, fasten the first H Joiner 995mm in from the edge of the structure. In the case of the rafters, the centre of the 2nd rafter should be installed 995mm from the outside edge of the first rafter. Centres of the internal rafters/H/H sections should be 1000mm apart, and battens must be a maximum of 1200mm apart.

- Screw through the centre of the H section by drilling a 5mm hole and then using a 12-gauge timber or metal screw with a neo. When installing the first and final panels, first attach the F section to the outside of the panel with the leg facing downward.

- Pull the protective film back on the sides of the sheet and place the rubber gasket on both sides of the sheet to be inserted into the H joiner. Then, use either the F section (barge ends) or the next H joiner on the side, away from the secured H joiner. Insert this section onto the sheet and into the secured H joiner by tapping it in with a rubber mallet, then secure the unsecured section as before. (This is not required with the F section)

- Repeat steps 6-8 until all sheets are positioned, and finish with the F section to the barge.

- Insert the aluminium End Cap on the bottom end (both top and bottom if free-standing). Do not stop at each glazing bar; this should be continuous if possible. Make sure to join aluminium sheet end caps at the alum joiner (if needed) so the joint is covered by the alum end cap lock.

- Insert the alum end cap by screw-fastening the cap lock to the H joiner cover. This will prevent the end cap from falling off due to sheet expansion and contraction.

What about the slope of the roof? The minimum recommended fall for Suntuf/Sunlite is 5 degrees. This keeps your sheets clean due to the right amount of rainfall, helps with waterproofing (so it doesn’t build up) and stops water from collecting inside the sheet. You don’t want dirty, mouldy roof sheets!

Read: What Colour Polycarbonate Roof Sheet Performs Best in Summer?

Sunlite Twinwall: Specifications

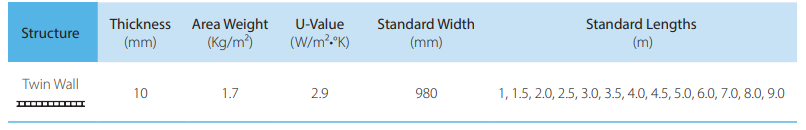

Here are the standard dimensions of Sunlite, from the thickness to the area weight, U-value, standard width, and standard lengths.

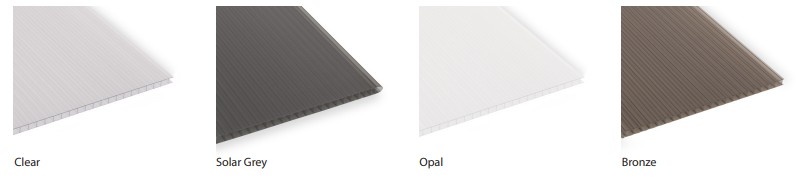

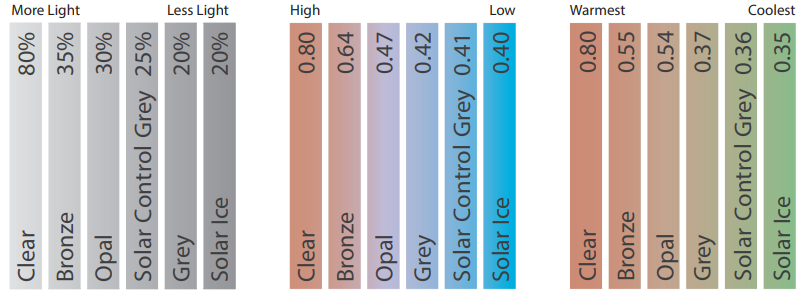

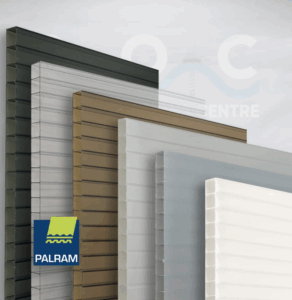

Standard colours include Solar Grey, Clear, Opal, Bronze, and solar control colours like Solar Control Grey, and Solar Ice. Clear is a good option if you want a brighter space without it generating heat (80% more light) while you’re hanging out with family and friends.

Different light and heat transmissions are available too, depending on your colour preference. Bronze offers 35% more light with a 0.64 shade coefficient (SC) and a solar heat gain (SHGC) of 0.55.

Solar Ice, for example, gives you 20% light, a low (0.40) shading coefficient, and a cool solar heat gain of 0.35. Opal is more of a mid-range, balanced option, with 30% sunlight, 0.47 shading co-efficient, and 0.54 solar heat gain co-efficient.

Are there general cleaning instructions for Sunlite?

Yes! All of the Palram polycarbonate products can be easily cleaned using a soft sponge or cloth made from 100% cotton, using lukewarm water and mild soap.

All surfaces should then be rinsed with cold water and dried with soft cotton to reduce water spotting. In some instances, this procedure may be inadequate and require the use of additional cleaning agents.

Is there a warranty post-installation?

Yes. Palram has a 10-year warranty too.

For light transmission, Sunlite won’t lose more than 6% of its light-transmitting capability for a period of 10 years from the commencement date, as a direct and exclusive result of solar radiation impact (as measured pursuant to the procedures specified in ASTM D-1003-77).

The product shall not display a change in yellowness of more than 10 units delta in the case of a transparent, clear product. Sunlite won’t break due to loss of impact strength and the exclusive result of weathering, impact of hail up to 13. (0.5” in diameter), attaining a velocity of up to 20 m/s (44.7mph).

An excessive loss of impact strength will be determined by test according to ISO 6603/1-1985(E) and/or ASTM D-5628-95 method F to be applied on a sample of the broken sheet. The 10-year warranty applies only if the sample is brittle or shattered into pieces.

If you’re ever unsure about the installation process, don’t hesitate to reach out to an experienced roofing contractor. Experts in roofing supplies from Colorbond sheets to panels, downpipes, flashing and DIY kits, the Roofing Options team is happy to direct you to a licensed roofer.

Read: Consider These Roofing Trends for Your Next Roofing Project.

Order Sunlite Twinwall from Roofing Options!

Welcome to your one-stop shop for quality Sunlite Polycarbonate in Melbourne. Sourcing superior materials for your construction projects has never been easier or more convenient with the Roofing Options Centre.

Providing the best selection of Sunlite polycarbonate in Melbourne, our dedication to premium quality and sustainable building practices sets us apart from the competition.

Sunlite 10mm Twinwall Polycarbonate

- Profiles Available: 10mm Twinwall

- Standard Width (per sheet): 980mm

- Min. Roof Pitch Required: Min 5 degrees

- Max Rafter Centres: 1000mm

- End Purlin Span: 900mm Mid Purlin Span: 1200mm

NOTE: The Sunlite fixing system is not available through our online store. Please contact us directly for a quote or any further information.

Trustworthy Roofing for Melbourne Properties: Buy Sunlite Twinwall!

Whether you need to order roofing supplies to your Frankston, Cranbourne, Dandenong, Carrum Downs, Officer, Berwick, Narre Warren, Clyde, or Endeavour Hills residence, Roofing Options delivers to you.

Do you need steel roof sheets, custom made flashings, Sunglaze, Suntuf Beehive, Suntuf EZ Glaze, Ampelite Solasafe, Laserlite 2000 & 3000, or Palram Sunsky? Talk to us.

For any installation advice or queries about our products, please feel free to contact us at 03 9354 2633 (Coburg), 03 8339 1150 (Campbellfield) or 03 9702 3301 (Cranbourne) or visit us in store.